Inside the Master’s Shop

Nick Sherburne is the Executive Vice President of Operations at Club Champion. That title might lead you to believe he sits in an office all day rearranging spreadsheets. However, Nick is one of the most skilled and passionate club builders you’ll find, frequently found in the build shop tinkering. He sat down with me recently to share some secrets for elevating your club building.

The Right Tools

While you don’t need every one of these tools right away, this is Nick’s list of tools for a complete shop:

- Heat gun

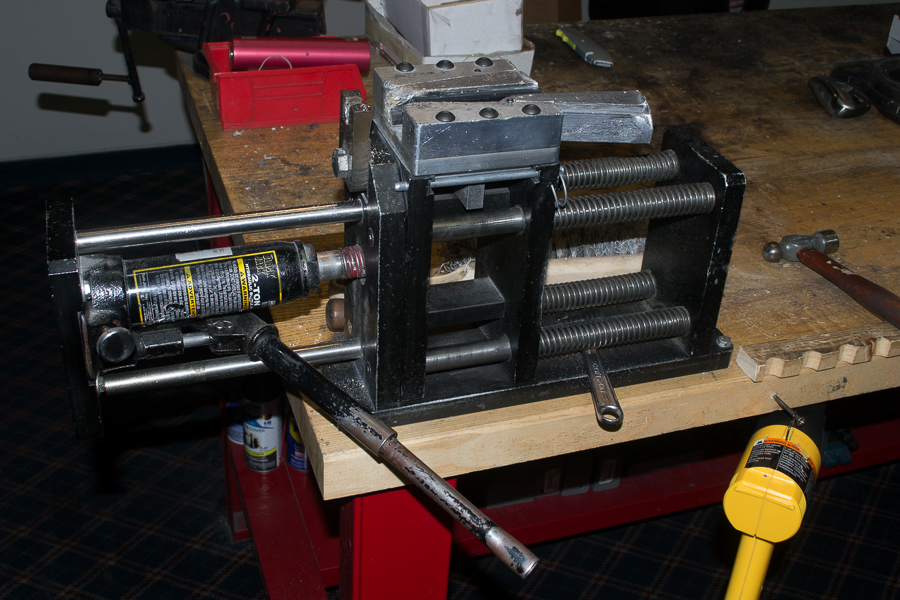

- Shaft puller

- Belt sander

- Swingweight scale

- Cut off saw

- Utility knife with straight and hook blades

- Vise

You’ll also need supplies like epoxy, two-sided tape, and ferrules.

When asked about his philosophy on buying tools, Nick stressed buying quality. Poor tools create headaches down the road. Club Champion uses primarily Mitchell tools and Golfsmith digital swingweight scales.

Installing Grips

Replacing golf grips is one of the best ways to get into club building and save some money. It’s not a complicated process, but Nick noted that there are several mistakes that amateur builders frequently make.

- Scratching the shaft when cutting off the old grip

- Not cleaning the old tape off the shaft

- Not using the right length of tape, leaving the grip uneven at the bottom

- Not getting the grip on all the way on or stretching it out too much

Nick also provided us with several pro tips for making the job go faster

- Having a tape dispenser makes the job easier

- Using a heat gun to heat old tape makes peeling it off much quicker

- Use plenty of solvent for faster and easier installation and alignment

Finally, on the longstanding question of gripping with pressurized air vs. solvent, Nick says that either method works, but he prefers solvent. He finds solvent to be easier when trying to line up a grip precisely.

If you’re interested in changing your own grips, get the step by step instructions HERE.

Pulling Shafts

Removing a shaft from a club is often step two in a new club builder’s journey. Nick repeatedly stressed the importance of a good shaft puller for this operation. Having a quality shaft puller allows you to use less heat. Using less heat gives you the ability to reuse the shaft and keep the head from having issues with paint or integrity.

Nick also stressed the importance of having a good pipe cleaner to clean out the hosel after a shaft pull. If you don’t get all the debris out of the hosel, your next installation could be compromised.

I asked Nick how many times a shaft can be used before you lose performance or risk breakage. He told me that “it’s really hard to screw up steel” but even a graphite shaft can be used many times if it’s pulled well.

On the question of separating pros from amateurs, Nick referenced the ability to pull a shaft without compromising the head or shaft. “It’s very easy to burn the paint on the head, or discolor the chrome on steel, or in todays multi-material heads ruin the actual materials the head is made from. Also a professional can pull and reuse a shaft 100 times due to having great pullers that allow for less heat use, keeping all materials like new.”

Weights & Measures

Weighing and measuring golf clubs seems straightforward, but Nick warned that there are several common mistakes that amateur builders make.

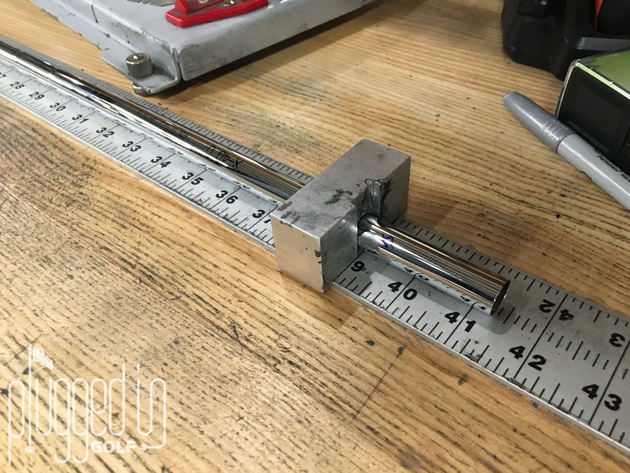

- Not using a club measuring jig

- Neglecting how much length the grip cap will add to a club

- Not calibrating your swing weight scale correctly

- Not calibrating your loft and lie machine

If you avoid these common errors, you should be well on your way to measuring like a pro. Get step by step instruction on how to Measure & Adjust Swing Weight HERE

Prepping Shafts

To prep steel and graphite shafts, Club Champion uses a belt sander with 80 grit sandpaper. Nick stressed that you do need to be careful with this method as it can remove material quickly. Prepping the shaft by hand can be safer for novice builders.

The keys to prepping a shaft well are:

- Not over prepping

- Not prepping too high up the shaft

- Making sure you clean the shaft

The trick, of course, is knowing the difference between under and over prepped. Nick told us that “As long as the surface is rough, you are prepped well enough.”

Get the step by step on shaft prepping HERE

Cutting Shafts

For both steel and graphite shafts, Nick uses a chop saw with a 0.035″ cut off wheel. Nick states that this creates a thinner, more accurate cut than alternatives like hacksaws or pipe cutters. It also helps to avoid frayed ends when cutting a graphite shaft.

Find our full Shaft Cutting 101 HERE

Golf Club Assembly

Before you actually put a club together, you need to choose the right epoxy. Nick told us that any epoxy you buy from a reputable golf distributor – Golfworks, Mitchell – should be fine, and he pointed out the more expensive 810 and 420 from 3M as excellent, also.

Within a given brand, you’ll have the choice between quick setting epoxy – often ready to play in 30 minutes – and long setting which requires 24 hours to cure. Nick recommended long set epoxy for novice builders as it gives them more time and often creates a better bond.

When you’re ready to glue up a club, here are the key mistakes you want to avoid:

- Not mixing epoxy thoroughly

- Not using enough epoxy

- Not abrading the shaft and hosel enough

- Not cleaning the hosel well enough

- Not having a tight fit

The solutions to these problems are all intuitive. Take the time to mix your epoxy. Nick says you can’t over mix, you can only under mix. Similarly, there’s no such thing as over gluing. Excess glue can create extra clean up work, but that’s far superior to a club coming apart. Finally, make sure the shaft and hosel have a tight fit, using shafting beads if necessary.

Find our Club Building 101 lesson on assembly HERE

Ferrules

Ferrules don’t serve a performance function, but they’re the clearest indicator of a professionally built club. Turning a ferrule properly requires time and the right equipment.

At Club Champion, turning a ferrules starts with a belt sander that has an Egyptian cloth belt. Nick recommends a ferrule turning arm to make the process easier. The next step is using steel wool to smooth the ferrule further. Finally, they wipe down the ferrule with acetone on a paper towel to give it a shiny finish.

Nick also noted that Club Champion always glues the ferrules to the hosel. This is a small step that ensures the ferrule won’t ride up the shaft over time.

Get the full step-by-step on turning ferrules HERE

Getting a Professional Look

Nick noted three aesthetic checkpoints that can keep a club from looking professional:

- Epoxy left on the head or shaft

- Uneven, unpolished ferrules

- Marks on the hosel from bending

Beyond the looks, Nick says that consistent, accurate swing weight is the #1 thing that separates amateur builders from the pros.

To make that leap to A Tier, Nick emphasized the importance of proper machinery, repetition, and finding a mentor who can teach you the proper technique.

He founded Plugged In Golf in 2013 with the goal of helping all golfers play better and enjoy the game more.

Matt lives in the northwest suburbs of Chicago with his wife and two daughters.

- Performance Golf Click Stick Training Aid Review - October 18, 2024

- Callaway Opus Platinum Wedge Review - October 17, 2024

- When to Take a Break from Golf - October 15, 2024

One Comment

Great article (and other added articles as well). I’m getting ready to start doing my own club work and have pretty much everything I need. I won’t have the larger bent sander and ferrule turner, but I’ll just do those items by hand using the vise and sandpaper.

Keep these types of articles coming!